- 1•877•542•7874

- info@HighGroundEquipment.com

- New England Parts & Service Support

Terex® Finlay tracked mobile jaw crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling construction waste. The Finlay range of jaw crushers are designed to meet the toughest demands of primary crushing applications with their impressive power, reliability and proven performance.

The second generation Terex Finlay J-1160 primary mobile jaw crusher was designed with the customer and operator in mind. The machine has been designed with increased under jaw clearance and all round preventative maintenance and serviceability access.

The heart beat of the machine is the renowned and aggressive Terex 1000 x 600mm (40” x 24”) jaw crusher with a proven pedigree in recycling, demolition and aggregate production applications. The hydrostatic drive gives the operator the flexibility of variable crushing speed and the ability to run the chamber in reverse in certain applications.

Designed to maximize fuel efficiency and deliver one of the lowest cost per ton in the market place the machine is the ideal solution for small to medium sized operators.

Features:

The robust high performance hydrostatic driven single toggle jaw chamber provides high capacity with large reduction ratio’s.

Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity.

High powered hydrostatic drive ensures precise chamber controls and reverse functionality for clearing blockages and assisting in demolition and recycling applications.

Fully hydraulic adjustable closed side setting minimises downtime and offers quick adjustment.

J-1160

| Specification | Value |

|---|---|

| Net Engine Power: Stage IIIA Constant Speed | John Deere 6068 284hp |

| Net Engine Power: Tier 4F / Stage IV | Caterpillar C7.1 275hp |

| Inlet Opening | 40″ x 24″ |

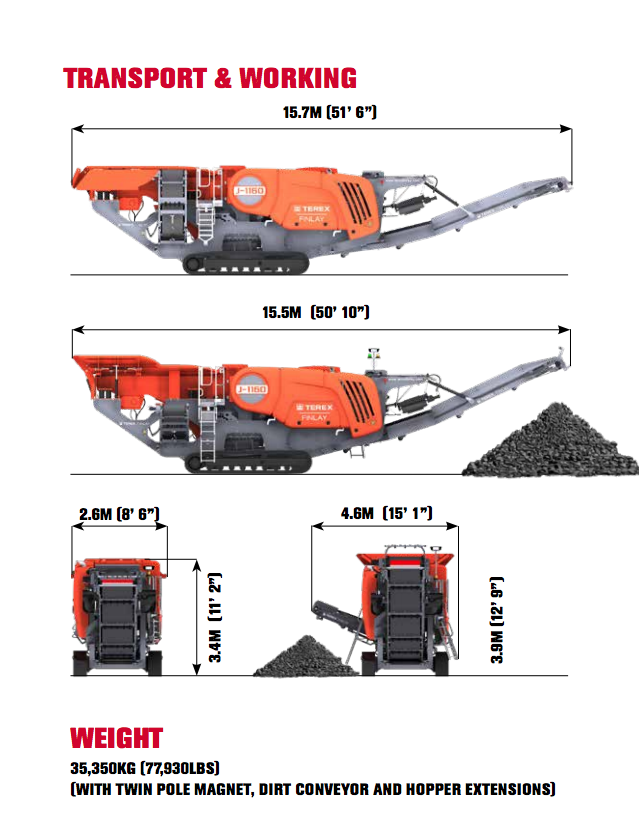

| Operating Weight | 77,930lbs |

The Terex Finlay J-1170 is a compact and aggressive tracked jaw crusher. The heartbeat of the machine is a robust hydrostatically driven Terex jaw chamber which provides high capacity with large reduction ratios. The jaw chamber configuration can be set up specifically for either processing construction demolition debris or quarrying applications.

The J-1170 features a heavy duty variable speed VGF and integrated prescreen giving excellent production throughput in quarrying, mining, demolition and recycling applications. Notable options include a variable speed pan feeder along with an independent prescreen system. Its compact size, quick set up times, ease of transport and user friendly operational features make the J-1170 ideal for all sized operators.

Features:

- The robust high performance hydrostatically driven single toggle jaw chamber provides high capacity with large reduction ratios.

- Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity.

- High powered hydrostatic drive ensures precise chamber control and reverse functionality for clearing blockages and assisting in demolition and recycling applications.

- Hydraulically assisted closed side setting adjustment minimises downtime and offers quick adjustment.

J-1170

| Net Engine Power: Tier 3 / Stage IIIA | Caterpillar C9 350hp |

| Net Engine Power: Stage IIIA Constant Speed | Scania DC09 365hp |

| Net Engine Power: Tier 4F / Stage IV | Scania DC09 345hp |

| Inlet Opening | 44″ x 28″ |

| Operating Weight | 107,806lbs |